Climate Challenges for Solar in Southeast Asia: Rain, Heat & Wind

August 13, 2025

Southeast Asia lies within tropical and subtropical monsoon zones, enjoying abundant solar irradiance year-round, which makes it one of the most promising emerging markets for photovoltaic (PV) development. However, the regional climate also introduces technical challenges. Among these, heavy rainfall and high humidity are particularly critical factors that impact the long-term safety and reliability of PV systems. This article focuses on how these two environmental conditions affect PV deployment and system design in the region.

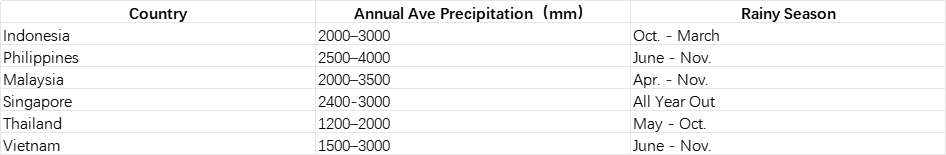

Year-Round Rainfall and Humidity

Southeast Asia experiences heavy rainfall and extended wet seasons. As shown in the following chart, the rainy seasons in different countries usually occupy around 6 months within one year. The average annual relative humidity across the region ranges from 75% to 95%. These conditions significantly accelerate the electrochemical corrosion of metal components and aging of sealing materials.

This makes water leakage a common problem, especially for metal roofs which has conventional modules on, acting as the most common target areas for distributed PV systems. Normally speaking, rail-based racking systems require screw anchoring into the roof, which will need penetrations to the roof. Waterproofing of this application often relies on rubber gaskets and waterproofing sealants. However, the harsh environment accelerates the degradation of these gaskets, which turns out that these measures will fail in an even shorter period. We have received complaints about this problem from our customers, whose waterproofing measure has failed in less than three years. Having a hard time dealing with the water leakage problems raised by the gasket failing problem, they found GoodWe for a non-penetrating PV solution.

From two aspects, GoodWe PVBM offers solutions aiming to reduce and solve the water leakage problem brought by PV installation.

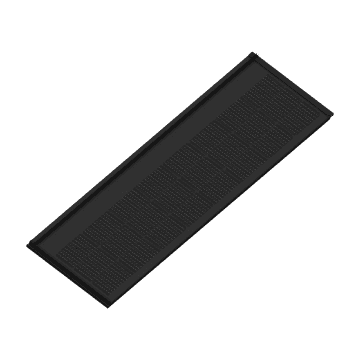

1.Non-Penetrating Installation to Prevent Roof Leakage

Based on the concerns of water leakage and low load-bearing capacity, GoodWe develops Galaxy Lightweight product. Featuring with only 5.6 kg/m², the product adopts a frameless design, allowing a non-penetrating standard installation method for multiple application scenarios. On metal roofs, the system can be installed using structural adhesives or clamps depending on the roof profiles. For trapezoidal metal roof and long-span roof which is quite common in some Southeast Asia market, structural adhesives can be used to install GoodWe Galaxy products. By applying adhesives to ribs of the metal roofs and then putting the Galaxy lightweight product on, it can be easily installed on the roof. The whole process only needs few accessories, thus resulting in high installation efficiency. It is quite popular among clients as labour costs could be saved.

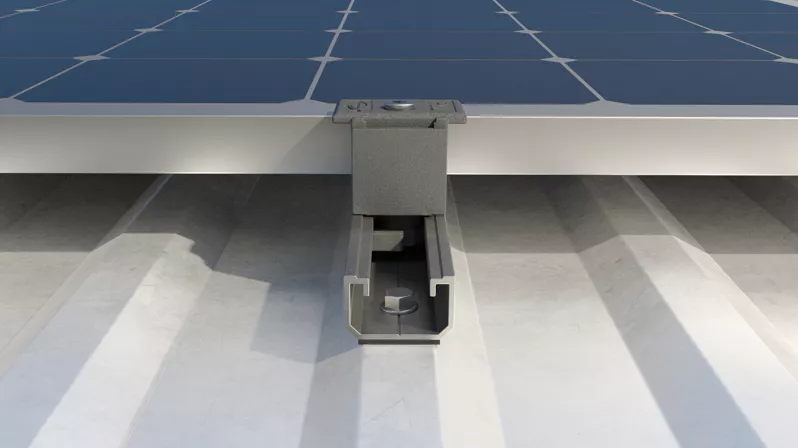

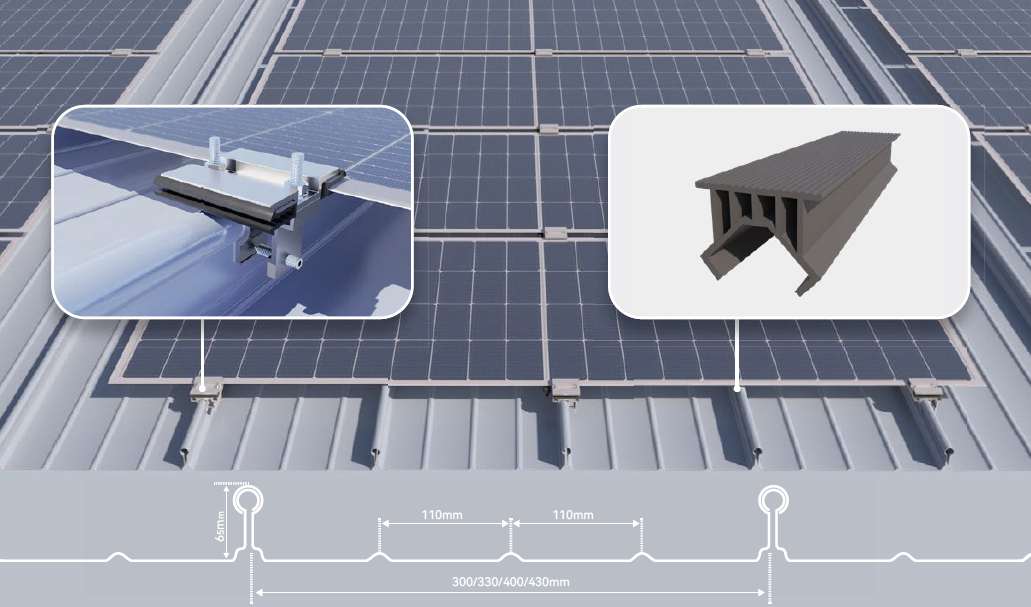

For the metal roof such as standing seam and Kliplok, specifically designed clamps can be used to install Galaxy lightweight products. So far, GoodWe has developed different clamps for different countries and regions based on research and profiles met in projects. For projects where standard clamps are not compatible with the existing roof profiles, GoodWe offers customization services. We provide tailored design and engineering support to develop project-specific mounting solutions, ensure proper fit and structural safety to satisfy clients' requirements.

For some rooftops with waterproof-membranes, where traditional penetrations would void the membrane warranty, Galaxy Ultra modules use a hot-air welding method to achieve a completely non-invasive installation.

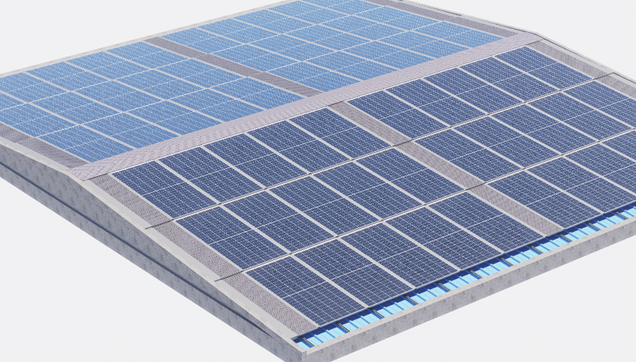

2. Double-Layer Roof System to Prevent Rusting

In addition to leakage caused by penetrations, the combination of constant rain and intense direct exposure to the sunlight often leads to surface corrosion of metal roofs after 6–7 years' usage. Large-scale rusting is particularly common with coated steel tiles, prompting building owners to consider full roof replacement. GoodWe offers a double-layer roof system by using GoodWe’s Polaris product. The product integrates the water drainage within the frame. With the dedicated designed product frame and coverplate, a water channel inside the frame will be formed by the adjacent Polaris products after installation. And for the product in different lines, the products will be partially overlapped, just like the tiles on the slope roof. During rain, water will flow over the surface or be guided into the drainage channels inside the frame. GoodWe can also provide specially designed maintenance channel metal plate, which can work properly with the Polaris product. This creates a continuous waterproof layer formed by PV modules that covers the existing roof, helping to delay or eliminate the need for roof replacement over the long term.