GoodWe's Solution for Highly Corrosive Environments in Southeast Asia

December 31, 2025

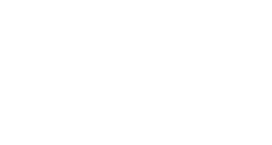

With the accelerated advancement of the global energy transition, photovoltaics, as a key player in the clean energy sector, is expanding rapidly across the globe. Endowed with abundant solar resources, Southeast Asia has witnessed remarkable growth in PV installed capacity. However, the region’s geographical characteristics of extensive coastlines have created an extremely demanding environment for PV products—high salt mist corrosion. Southeast Asia ranks among the highest in terms of salt mist levels worldwide. Coupled with harsh local environmental conditions such as high humidity and intense ultraviolet radiation, salt mist corrosion has become a critical technical challenge affecting both the reliability and economy of PV systems, directly influencing the long-term stability and return on investment of projects.

As one of the core components of PV systems, PV modules exhibit multi-component, multi-mechanism, and progressive failure modes in salt mist environments. Salt mist corrosion impacts PV modules through multiple interacting failure mechanisms, primarily affecting the following components: aluminum alloy frames, glass encapsulation layers, encapsulant materials, backsheets, and solar cell electrodes.

Metal Frames: Chloride ions can easily break down the surface passivation film, triggering pitting corrosion and intergranular corrosion. The volume expansion of corrosion products leads to frame cracking and structural loosening, ultimately allowing moisture to penetrate the module interior, inducing Potential Induced Degradation (PID), and causing a significant drop in power output.

Encapsulant Materials: Commonly used EVA encapsulant films, due to their molecular structure containing hydrophilic groups, are prone to hydrolysis in salt spray and humid environments. In contrast, POE encapsulant films possess a stronger salt spray resistance. With a lower vapor transmission rate, the degradation rate is far lower than that of EVA. Withstanding a long-term salt spray corrosion, it can more durably block corrosive media from penetrating directly into the module interior, making it a preferred choice for high-salt-spray environments.

Delamination of Solar Panels, Failure modes of standard photovoltaic modules in Sahara Desert. IREC 2020

Backsheets: Chloride ions easily penetrate the protective layer, and defects in the encapsulation process become "breakthrough points"—if the edge sealant is unevenly applied during encapsulation, poorly bonded to the frame, or if the selected sealant has insufficient aging resistance, the sealant layer will shrink and crack after a short period. Salt mist will quickly penetrate along the gaps, causing the backsheet edges to bulge and peel off first.

PV Mounting Structures: As the "load-bearing framework," they bear the brunt of salt mist—after the zinc layer of galvanized steel brackets is damaged, large-scale rust formation will appear within 1 year; aluminum alloy brackets are prone to dense pitting corrosion. Bracket deformation will cause the module tilt angle to shift, reducing power generation efficiency by 4%-6%, and in severe cases, structural collapse will result in mass module damage.

Connecting Bolts: Contact between different metals (e.g., steel bolts + aluminum brackets) is prone to galvanic corrosion, and salt accumulation on threads can lead to crevice corrosion. After the loss of bolt preload, modules may loosen and vibrate, which not only aggravates frame wear but also creates new pathways for corrosion, ultimately potentially causing safety issues.

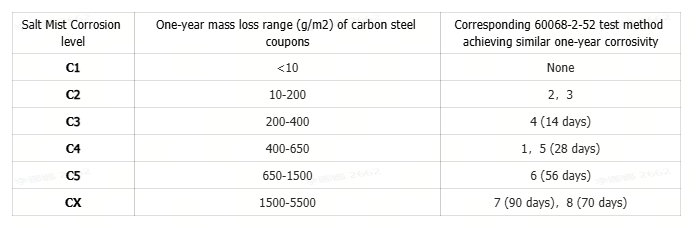

To verify the reliability of modules in salt mist environments, relevant guidelines from both PV module and environmental parameters perspectives have been defined. For PV modules, salt mist certification must comply with international standards. Currently, the globally recognized core standard is IEC 61701, following which PV module salt mist corrosion testing is conducted in accordance with IEC 60068-2-52. The test procedure can be divided into three parts:

Pre-testing: Conduct initial sample inspections first, including visual inspection, maximum power measurement, insulation testing, and other performance test items on the samples;

Salt mist test: Perform the test according to the method specified in IEC 60068-2-52;

Post-test verifying: After the test, clean and recover the samples, then complete the re-test of component performance to compare the impact of the salt mist test on the components.

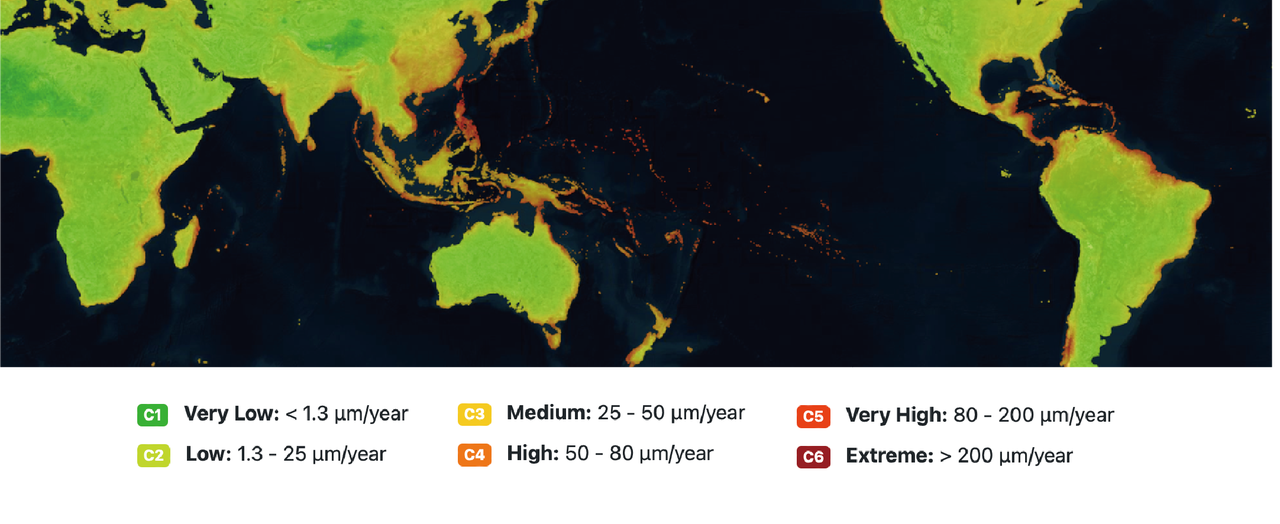

The salt mist testing procedure includes 8 specific test methods, with different settings for test conditions, cycle duration, and total number of cycles based on various salt mist environments, aiming to simulate different failure mechanisms in diverse real-world based scenarios. From least to most severe:

Salt Mist 1-2: Exposed to long-term, stable high-salt and high-humidity environments;

Salt Mist 3-6: Aiming to recreate the most terrestrial outdoor environments, including coastal cities and industrial areas, where regular day-night alternations and sunny-rainy changes occur;

Salt Mist 7-8: For moving objects such as automobiles, the corrosion environment is dynamic and extreme. Rapid hot air drying is the key here—it greatly accelerates the corrosion rate through extreme temperature changes.

In terms of environmental parameters, ISO 9223 classifies atmospheric corrosivity into six levels from low to high: C1 (Very Low), C2 (Low), C3 (Medium), C4 (High), C5 (Very High), and CX (Extreme). Each level corresponds to a clear "corrosion rate range + environmental characteristics + typical scenarios," as shown in the table below:

International Organization for Standardization. (2012). ISO 9223:2012: Corrosion of metals and alloys - Corrosivity of atmospheres - Classification.

In practical applications, many customers attempt to assess the salt mist corrosion level based on the distance from saltwater bodies. So far, no scientific and direct correspondence between distance and salt mist corrosion level has been drawn, mainly due to the salt mist level is manipulated by several different parameters. For example, at the same distance of one kilometer from the ocean, the windward side (e.g., coastal cliffs) may correspond to the CX level due to direct salt mist impact, while the leeward side (e.g., coastal depressions) may only correspond to the C4 level due to topographical obstruction. Temperature variations in different regions will also lead to differences in atmospheric salt mist concentrations, resulting in different salt mist levels. Therefore, corrosion classification must be based on environmental parameters rather than distance alone.

Against this backdrop of corrosion risk and rigorous testing, structural design becomes a decisive factor in long-term module reliability. GOODWE Galaxy lightweight modules have passed Salt Mist Test 6, suitable for use in C5 salt mist environments. Compared with conventional framed products, the GOODWE Galaxy frameless single-glass PV product inherently possesses anti-salt mist advantages in structural design:

Core Advantage 1: Frameless design eliminates the corrosion hot spot. The Galaxy product abandons the traditional aluminum alloy frame, directly eliminating the metal carrier most vulnerable to salt mist corrosion, structurally cutting off the chain failures caused by frame corrosion, and enhancing the reliability of long-term system operation.

Core Advantage 2: Single-glass encapsulation strengthens the protective closed loop. The combination of high-strength tempered glass and selected encapsulant films ensures resistance to salt mist corrosion while achieving product lightweighting.

Core Advantage 3: Innovative structure reduces sealing risks. The GOODWE Galaxy lightweight module innovatively adopts a “film extrusion” lamination process for the combination of the module and edge protection. Meanwhile, the extruded film naturally forms a barrier between the module interior and the external environment, minimizing the potential harm of salt mist corrosion to the module interior.

Salt mist corrosion is not a single-point failure risk, but a system-level challenge driven by materials selection,structural design, and environmental exposure conditions. Reliable PV deployment in high-corrosion regions requires evaluation based on internationally recognized standards rather than simplified assumptions such as distance from the coastline. By combining rigorous salt mist testing with corrosion-aware structural design—particularly through frameless architecture, optimized encapsulation systems, and enhanced edge protection—PV modules can achieve greater long-term reliability and performance stability in harsh coastal environments, ultimately safeguarding the project's lifetime value and ROI.