Solar Module or Safety Glass? Why We Tested Polaris to German Construction Standards (DIN 18008)

January 30, 2026

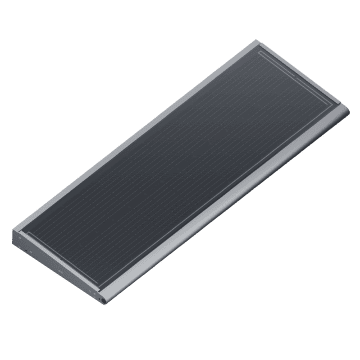

In the world of Building Integrated Photovoltaics (BIPV), there is often a disconnect between the "PV world" and the "Construction world."

As solar professionals, we talk about efficiency, degradation rates, and yield. But when we speak with architects and façade consultants, their first question is rarely about watts. It is about liability.

"What happens if a maintenance worker falls against this façade?""If a storm breaks the glass canopy, will it shatter and fall on pedestrians?""Can I legally specify this as overhead glazing?"

To answer these questions definitively, we decided to go beyond standard IEC certification. We collaborated with two of Germany's leading institutions: the accredited laboratory Friedmann & Kirchner and the Friedrich-Siemens-Laboratorium at TU Dresden.

Polaris: Proven Safety & Durability

Here is what we found, and why it matters for your next project.

1.The "Human Impact" Test: Proving Structural Integrity

One of the biggest myths in BIPV is that embedding solar cells inside the glass laminate creates "weak points" that compromise structural integrity.

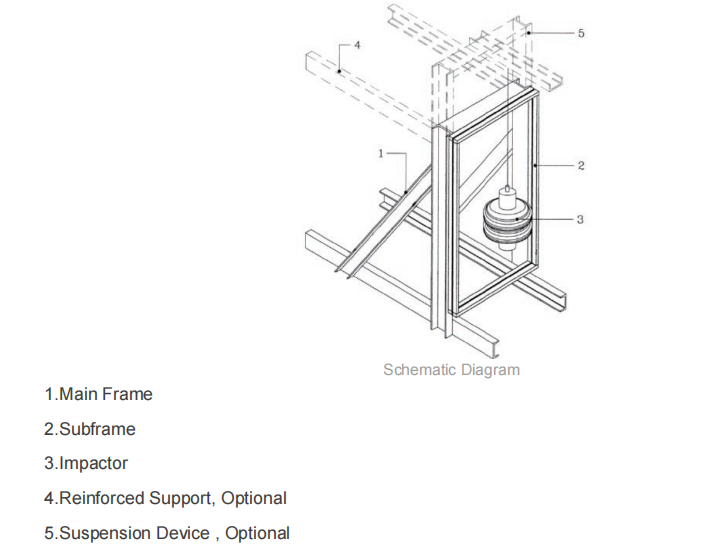

To test this, we performed the Pendulum Impact Test (DIN EN 12600). This involves swinging a 50kg dual-tire impactor from various heights directly into the center of the glass module. It simulates a human body impacting a window or a skylight.

The Result: The Polaris module demonstrated safe breakage behavior. Crucially, the laboratory report concluded that "the embedded solar cells have no significant influence on the breakage behavior under dynamic stress". What this means for you: You can specify Polaris with the same confidence as standard architectural laminated glass. It protects occupants and meets the safety requirements for vertical glazing in public areas.

2.The Emergency Scenario: Residual Load Bearing

For overhead applications—like carports, atriums, or sunrooms—the nightmare scenario for any engineer is "post-breakage behavior." If a heavy object hits a glass canopy, even if the glass fractures, will the module remain in the frame long enough for people below to move to safety?

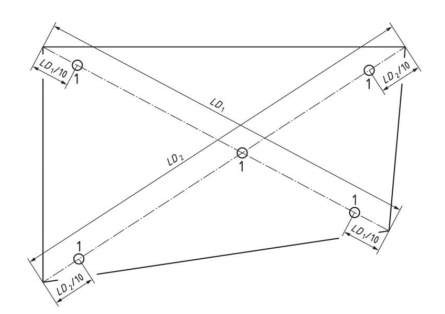

We tested this using the Residual Load Bearing Test (Resttragverhalten).

We deliberately broke both layers of the glass laminate.We loaded the broken "blanket" of glass with 130 kg (13 sandbags) to simulate residual load after glass breakage.We waited.

Schematic Diagram

The Result: After 24 hours under a 130kg load, the module did not collapse. It remained safely in its frame with no dangerous falling fragments.

This "Golden Evacuation Time" is critical. It proves that thanks to our premium encapsulation and lamination process, the module retains structural cohesion even in the unlikely event of catastrophic damage.

3.Beyond the Standard: 2000 Hours of Durability

Construction materials are expected to last for decades, often outliving standard electrical equipment. To ensure Polaris matches the lifespan of the building skin, we pushed the weathering tests further.

While many standard tests stop at 1,000 hours, we subjected Polaris to 2,000 hours of intense Radiation Testing (Ultravitalux). The result? No visual defects or failures.

Summary: Bridging the Gap

The data from Friedmann & Kirchner confirms what we at GoodWe PVBM have always believed: Polaris is not just a solar panel; it is a certified building material.

By meeting the DIN 18008 standards for Laminated Safety Glass, we have removed the safety and liability barriers that often stall BIPV projects. Whether you are designing a commercial carport in France or a public building in Germany, you now have the third-party verification to design with confidence.

Application Scenario