Climate Challenges for Solar Deployment in Southeast Asia: High Rainfall, Extreme Heat and Strong Wind(2)

September 01, 2025

Most Southeast Asian countries are located near the equator, where high temperatures are consistent year-round. Average temperatures in many areas exceed 28°C, with daytime highs frequently surpassing 35°C. As distributed PV systems are installed on building rooftops, where ambient heat is compounded by strong solar radiation, module surface temperatures often rise 30–40°C above ambient, placing stress on module performance.

This demands high standards in both product design and installation methods to mitigate heat-related performance degradation.

1.Installation Method and Heat Dissipation Channel

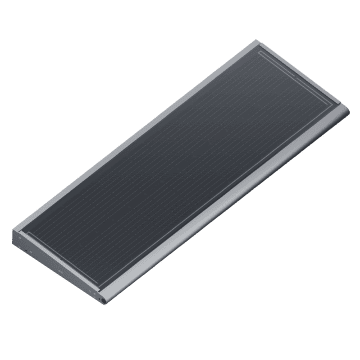

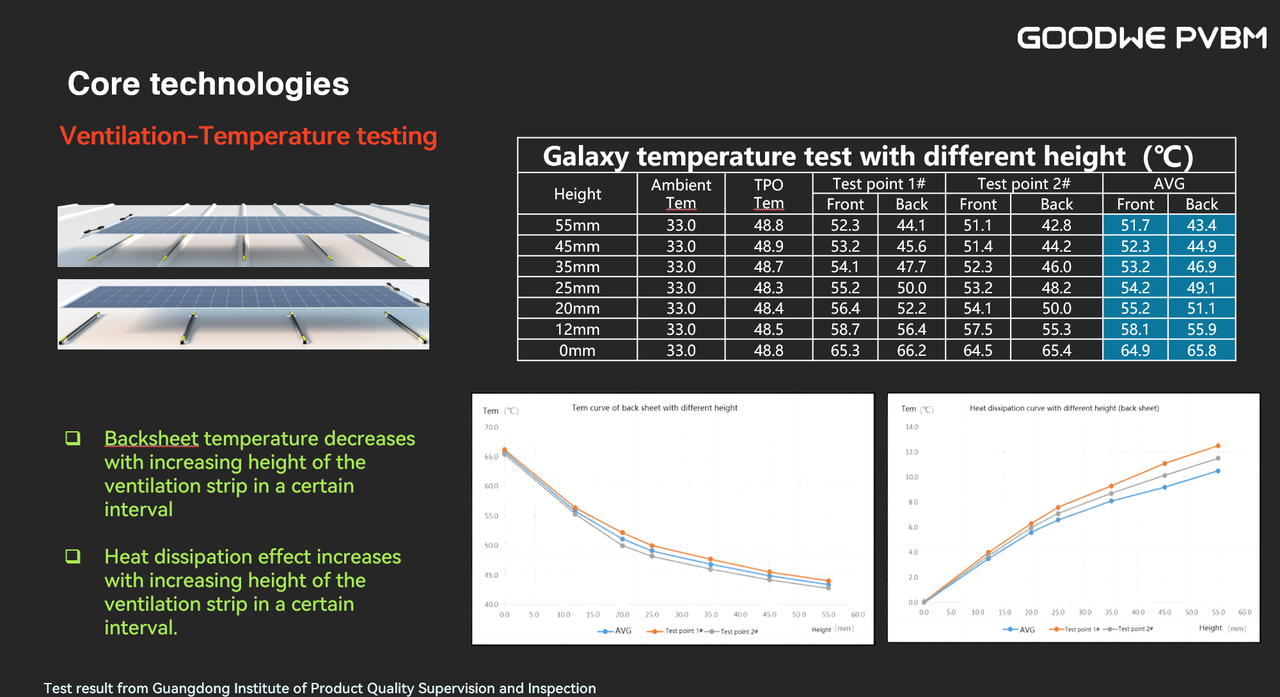

The way modules are mounted significantly affects their ability to dissipate heat. Conventionally, frameless modules often rely on full-surface adhesive bonding, which may damage roofs due to thermal expansion under extreme heat. GoodWe Galaxy lightweight modules incorporate dedicated ventilation channels beneath the modules to promote cooling.

Galaxy Series is designed specifically for roofs with structural load limitations. Its rail-free installation further reduces system weight. During product development, GoodWe conducted extensive thermal optimization tests with rear-side air tunnels ranging from 0 to 55 mm. Results showed that increased height improved heat dissipation, but with diminishing returns. A 25 mm ventilation channel was identified as the optimal balance between thermal performance and system BOM cost.

Shadowing Scenario Test

GoodWe also conducted tests simulating partial shading conditions, which can lead to hotspot phenomenon. This is where extreme temperatures could exist on the panel, and potentially damage the roof material. When 30% of the module was shaded:

Without ventilation channel, the backsheet temperature reached 181°C, damaging the waterproof membrane underneath.With a 25mm ventilation channel added, the temperature dropped by 46°C, preventing membrane failure and maintaining safe operating conditions.

2. Selected material to optimize Temperature Coefficient performance

PV modules are temperature sensitive. For example, conventional P-type silicon modules have a typical temperature coefficient of -0.37%/°C, meaning a 40°C increase in module temperature results in around 14.8% power loss.

GoodWe’s Galaxy series uses N-type TOPCon cells with a lower coefficient of -0.30%/°C, reducing power loss under high temperatures to approximately 10%, thereby enhancing performance under typical Southeast Asian high temperature conditions.

In addition to heavy rain and high temperatures, several Southeast Asian countries, especially the Philippines and Vietnam are located in the Northwest Pacific typhoon belt, where cyclonic activity is frequent and intense:

The Philippines is one of the most typhoon-impacted countries in the world, experiencing 18–20 tropical storms annually, of which 6–9 are full-scale typhoons.Northern and central Vietnam typically faces 2–3 typhoons or tropical storms per year, with standard design wind speeds reaching 45–55 m/s.

These high wind speeds impose strict structural demands on both module integrity and installation methods. If the system cannot provide sufficient wind uplift resistance, modules can be lifted or dislodged under negative pressure, leading to system failure or serious safety incidents.

As a BIPV solutions provider, GoodWe PVBM prioritizes safety as a core principle. Before entering the Southeast Asian market, our engineering team conducted studies on wind climate and evaluated various installation methods.

For example, in the Philippines, where longspan metal roofing is commonly used, adhesive solution is the most suitable solution for applying Galaxy lightweight modules inside Philippine market. According to the NSCP (National Structural Code of the Philippines) and feedback from local client, a design wind speed of 250 km/h for buildings is commonly accepted.

We assume that the factory building has a height of 21 meters, a slope of less than 10 degrees, and is located in an unobstructed suburban area with a basic wind speed of 250 km/h. Since the factory building is of a standard structure, we can refer to Table 207B.6.2 in NSCP for lookup. The results show that Roof Area 3 (i.e., the corner area) is the maximum wind pressure area, with a pressure value of -3.12 kN/m². After that, we use the Exposure Adjustment Factor for correction, but since the factory building is in Exposure Category C, no correction is needed, so the final wind pressure remains -3.12 kN/m², meaning one panel will face 5203 N force in the highspeed wind.

For GoodWe Galaxy lightweight module, the standard installation guide allocates 5–6 adhesive strips per module, meaning each adhesive must resist 867–1040 N. By using the adhesives passed the testing criteria by GoodWe, each adhesive could at least provide 1900 N in real application, which is nearly doubled from the required force in the high speed wind. For most of the adhesive, test result has significantly exceed standard requirements, ensuring that the adhesive-based installation is safe and structurally robust even under typhoon conditions. For long-term reliability of the adhesives, tests have been done to have a preliminary evaluation on adhesive degradation. Coordinated with the adhesive manufacture, we have conducted environmental simulation tests on silicone structural adhesives under high-temperature and high-humidity conditions, including continuous water immersing, damp heat and temperature cycling. While the results cannot be directly mapped to actual aging years, the observed performance degradation remains well within the safety margins considered during adhesive selection.

The extreme climate conditions of Southeast Asia—high heat, humidity, rainfall, and wind—present unique challenges for PV systems. GoodWe PVBM addresses these with region-specific solutions that enhance waterproofing, cooling and structural resilience. With proven technologies and engineering support, GoodWe ensures safe, efficient and reliable solar performance across Southeast Asia’s most demanding environments.